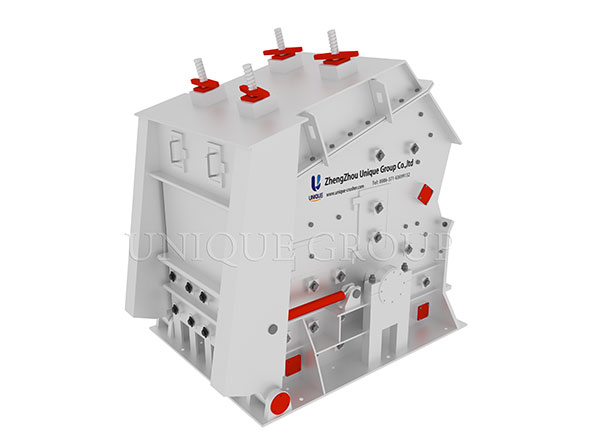

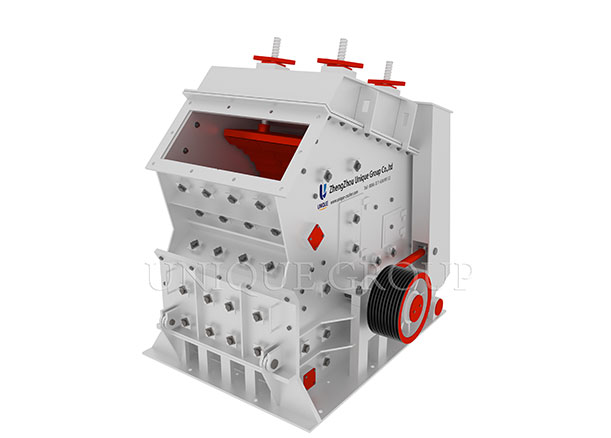

Impact Crusher

- Feeding Size: 300-500mm

- Capacity: 30-250 T/H

- Field: Ore crushing, production of construction aggregates, water conservancy...

- Materials: Granite, marble, basalt, limestone, quartz stone, river gravel...

- Engine Power: 45-132 KW

- Add to Favorites

- Find Us on

Overview

Impact crusher is able to crush coarse, medium and fine materials such as granite, limestone and concrete whose feeding granularity does not exceed 500mm and compression strength does not exceed 350MPa in many industries such as ore crushing, railway, highway, energy, cement, chemistry and constriction. The size of the discharging granularity is adjustable, and the crushing specifications are diverse.

Features and Benefits of Impact Crusher

1. Even crushing function of multi-cavities which is suitable to crush hard material

2. Reasonable design of leveling plate making the finished material finer and cubic-shaped without internal cracks.

3. Low and big feed opening make the production line easy to arrange and increase the size of feeding material.

4. Hydraulic start-up which is convenient for maintenance and replacement of wear-parts.

5. New anti-abrasive material which prolong service life of impact hammer, impact plate and liner.

Working Principle of Impact Crusher

The impact crusher driven by the electro motor, the rotor will rotate with high speed, and when the materials go into the action zone of the plate hammer, they will strike and are crushed on the plate of the rotor, and then are crushed again when they are thrown to the impacting device, and then the materials will bounce back from the impact lining board and go to the action zone of the plate hammer and are crushed again. This process will proceed repeatedly, and the materials go into the first, second and third impacting chamber to be crushed until they are crushed to the required granularity, and then discharged from the discharging mouth. Adjusting the gap between the impacting rack and the rotor can change the discharging granularity and the shape of the materials.

| Model |

Rotor Spec(mm) | Feed Opening Size(mm) | Max Feed Edge(mm) | Capacity (t/h) |

Motor Power(kw) | Weight (t) |

Dimensions (L×W×H) (mm |

| PF-1007 | 1000x700 | 400x730 | 300 | 30-70 | 45 | 12 | 2330x1660x2300 |

| PF-1010 | 1000x1050 | 400x1080 | 350 | 50-90 | 55 | 15 | 2370x1700x2390 |

| PF-1210 | 1250x1050 | 400x1080 | 350 | 70-130 | 110 | 17.7 | 2680x2160x2800 |

| PF-1214 | 1250x1400 | 400x1430 | 350 | 100-180 | 132 | 22.4 | 2650x2460x2800 |

| PF-1315 | 1320x1500 | 860x1520 | 500 | 130-250 | 220 | 27 | 3180x2720x2620 |

Introduzca sus requisitos, tales como el modelo, la cantidad de spray, aerosol rango, la capacidad del recipiente, le responderemos tan pronto como sea posible.

Tel: +86-371-63699132

Fax: +86-371-63935058

E-mail:

sales@unique-crusher.com

Zip Code: 450008

العربية

العربية Español

Español Português

Português Deutsch

Deutsch