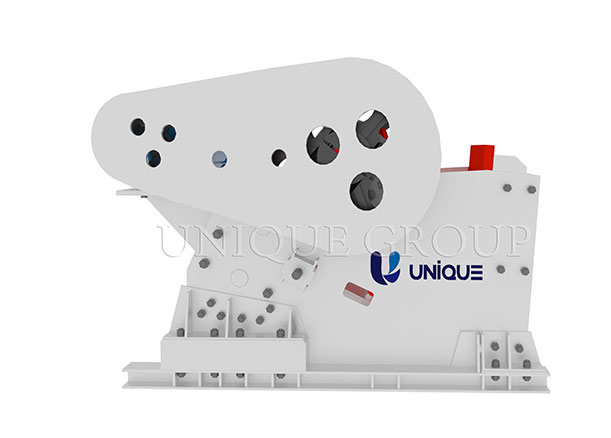

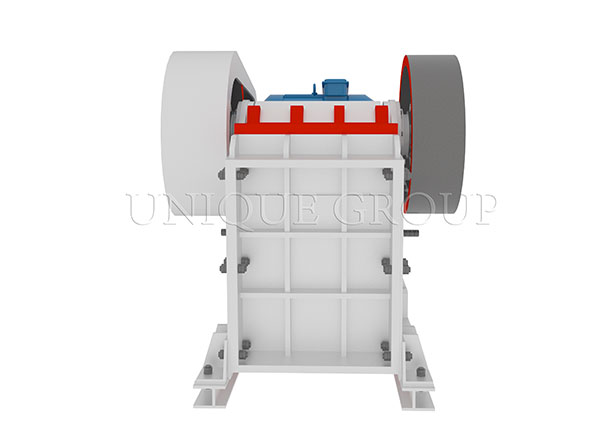

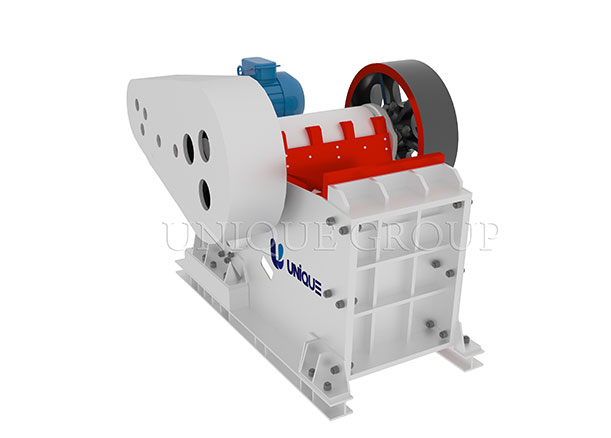

Jaw Crusher

- Feeding Size: 125-1020mm

- Capacity: 1-800T/H

- Field: Ore crushing, production of construction aggregates, water conservancy...

- Materials: Granite, marble, basalt, limestone, quartz stone, river gravel...

- Engine Power: 5.5-160KW

- Add to Favorites

- Find Us on

Overview

Jaw crusher is mainly used for the medium-granularity crushing of all kinds of ores and large materials in mine, metallurgy, building material, highway, railway, water conservancy and chemistry.With simple and solid structure, reliable work, easy maintenance and repair and low production and construction fees, it has long been widely used in many industrial departments such as metallurgy, chemistry, building material, power plant and transportation. The maximum compression strength of the materials to be crushed is 320MPa.

Features and Benefits of Jaw Crusher:

1.Simple structure,reliable operation,low operating costs,convenient maintenance;stable performance,low operating costs;crushing ratio

2.Crushing chamber depth and no dead zone,increased capacity and output feed

3.The crushing ratio,uniform particle size

4.Gasket nesting population adjustment device,reliable and convenient adjustment range,increase the flexibility of the device

5.Lubrication system is safe and reliable,easy to replace parts,maintenance workload is small

6.Saving equipment:stand-alone energy-saving 15% to 30%,saving more than double the system

7.Nesting population adjustment range,to meet the requirements of different users

8.Low noise,less dust.

Operating Principle of Jaw Crusher:

The working manner of this series crushing machine is dynamic extrusion type, and its working principle goes like this:This machine is driven by motor. Through the motor’s wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track. Therefore, the materials in the crushing cavity composed of fixed jaw plate, movable jaw plate and cheek plate can be crushed and discharged through discharging opening.

Main Specifications of our Jaw Crusher:

| Model | Max feeding Size (mm) |

Adjusting range of discharge opening(mm) |

Capacity (t/h) |

Motor power (kw) |

Total weight (t) |

Dimensions (L*W*H)(mm) |

| PE-150*250 | 125 | 10-40 | 1-3 | 5.5 | 0.8 | 720*660*850 |

| PE-250*400 | 210 | 20-60 | 5-20 | 15 | 2.8 | 1300*1090*1270 |

| PE-400*600 | 340 | 40-100 | 16-60 | 30 | 7 | 1730*1730*1630 |

| PE-500*750 | 425 | 50-100 | 40-110 | 55 | 12 | 1980*2080*1870 |

| PE-600*900 | 500 | 65-160 | 50-180 | 55 | 17 | 2190*2206*2300 |

| PE-750*1060 | 630 | 80-140 | 110-320 | 90-110 | 29 | 2660*2430*2800 |

| PE-900*1060 | 685 | 230-290 | 230-390 | 110 | 33 | 2870*2420*2940 |

| PE-900*1200 | 750 | 95-165 | 220-450 | 110 | 52 | 3380*2870*3330 |

| PE-1000*1200 | 850 | 195-265 | 315-500 | 110 | 55 | 3480*2876*3330 |

| PE-1200*1500 | 1020 | 150-300 | 400-800 | 160 | 100.9 | 4200*3300*3500 |

| PEX-150*750 | 120 | 18-48 | 8-25 | 15 | 3.8 | 1200*1530*1060 |

| PEX-250*750 | 210 | 25-60 | 13-35 | 30 | 5.5 | 1380*1750*1540 |

| PEX-250*1000 | 210 | 25-60 | 16-52 | 30 | 7 | 1560*1950*1390 |

| PEX-250*1200 | 210 | 25-60 | 20-61 | 37 | 9.7 | 2140*1660*1500 |

Introduzca sus requisitos, tales como el modelo, la cantidad de spray, aerosol rango, la capacidad del recipiente, le responderemos tan pronto como sea posible.

Tel: +86-371-63699132

Fax: +86-371-63935058

E-mail:

sales@unique-crusher.com

Zip Code: 450008

العربية

العربية Español

Español Português

Português Deutsch

Deutsch