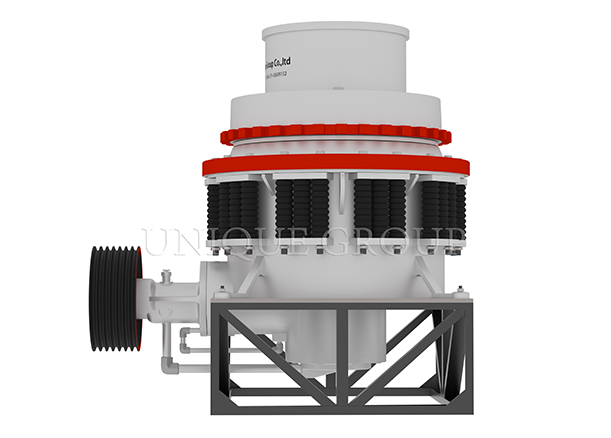

Spring Cone Crusher

- Feeding Size: 300mm

- Capacity: 15-1000 T/H

- Engine Power: 30-280kw

- Field: Ore crushing, production of construction aggregates, water conservancy...

- Materials: Granite, marble, basalt, limestone, quartz stone, river gravel...

- Add to Favorites

- Find Us on

Overview

Spring cone crusheris suitable for crushing all sorts of ores and rocks whick is medium or above medium hardness. Compare with jaw crusher, cone crusher is high efficiency, easy adjustment, economic operation and has stable structure, etc.It is widely used in metallurgical industry, hydro-dam construction, transportation, chemical industry and building materials.

Features and Advantages of Spring Cone Crusher:

1. Reasonable structure advanced crushing principle and technical specification, reliable work and low cost.

2. Strong crushing ability; High efficient productivity; High capacity.

3. Reliable Hydraulic system providing safe and effective overload protection.

4. Two type of crushing chamber are for wide range of product size requirement.

5. High automation adopting hydraulic adjustment and hydraulic clean cavity setting.

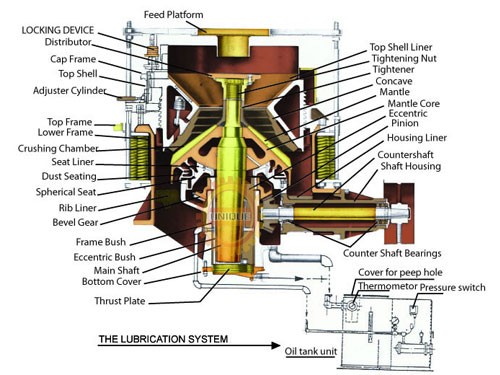

Working Principle of Spring Cone Crusher

The spring cone crusher crushes materials by the working surface between the movable cone and fixed cone. So it is more advanced and efficiency than jaw crusher. The movable cone is supported by spherical bearing and fixed on an hanging erect shaft which is set in the eccentric sleeve, and the sleeve is set on the stopping and pushing bearing. The movable cone and erect shaft are drived by the eccentric shaft sleeve together. The eccentric shaft sleeve is driven by horizontal shaft and fabricated gear, and the wheel of the conveyor belt is drived by motor through v-belts. The lower part of vertical shaft is installed in the eccentric sleeve. When the eccentric sleeve rotates, there is a conical surface lined out by the shaft. When the movable cone comes near the fixed cone, rocks are grinded into pieces, when the cone leaves, grinded materials is discharged from the discharge hole. The fixed cone can be ascended or descended by adjusting setting to adjust the width of discharge hole, consequently the output size is determined.

| Type | Dia. of cone (mm) |

Discharge setting (mm) |

Max Feed Size (mm) |

Capacity (t/h) |

Motor Power (kw) |

Weight (t) |

Overall Dimension (mm) |

| PYB-600 | 600 | 12-25 | 62 | 15-25 | 30 | 5.5 | 2800×1300×1700 |

| PYD-600 | 3-13 | 36 | 5-23 | 30 | 5.5 | 2800×1300×1700 | |

| PYB-900 | 900 | 15-50 | 115 | 50-90 | 55 | 10.18 | 3020×1640×2350 |

| PYZ-900 | 5-20 | 60 | 20-65 | 55 | 10.19 | 3020×1640×2350 | |

| PYD-900 | 3-13 | 40 | 15-50 | 55 | 10.27 | 3020×1640×2350 | |

| PYB-1200 | 1200 | 20-50 | 145 | 110-200 | 110 | 24.7 | 4152×2300×1980 |

| PYZ-1200 | 8-26 | 100 | 50-150 | 110 | 25 | 4152×2300×1980 | |

| PYD-1200 | 3-15 | 50 | 18-105 | 110 | 25.6 | 4152×2300×1980 | |

| PYB-1750 | 1750 | 25-60 | 215 | 280-480 | 155-160 | 50.6 | 6020×2948×4192 |

| PYZ-1750 | 10-30 | 185 | 115-320 | 155-160 | 51 | 6020×2948×4192 | |

| PYD-1750 | 5-15 | 85 | 75-230 | 155-160 | 50.5 | 6020×2948×4192 | |

| PYB-2200 | 2200 | 30-60 | 300 | 590-1000 | 260-280 | 84 | 7705×3432×5057 |

| PYZ-2200 | 10-30 | 235 | 200-580 | 260-280 | 85 | 7705×3432×5057 | |

| PYD-2200 | 5-16 | 110 | 120-370 | 260-280 | 85 | 7705×3432×5057 |

Introduzca sus requisitos, tales como el modelo, la cantidad de spray, aerosol rango, la capacidad del recipiente, le responderemos tan pronto como sea posible.

Tel: +86-371-63699132

Fax: +86-371-63935058

E-mail:

sales@unique-crusher.com

Zip Code: 450008

العربية

العربية Español

Español Português

Português Deutsch

Deutsch