Tel: +86-371-63699132

Fax: +86-371-63935058

E-mail:

sales@unique-crusher.com

Zip Code: 450008

What is gypsum and what is it used for? What equipment is needed for gypsum grinding? What is the process?

What is gypsum and what is it used for? What equipment is needed for gypsum grinding? What is the process?

According to its origin and form, gypsum can be divided into natural gypsum and industrial by-product gypsum. Natural gypsum includes alabaster, fibrous gypsum, etc. Among them, fibrous gypsum is a high-quality raw material for industrial processing because of its fibrous crystals and high purity; industrial by-product gypsum is a by-product produced in the industrial production process, such as desulfurization gypsum in power plants and phosphogypsum in phosphate fertilizer plants, which can be recycled after treatment.

1. Main uses of gypsum

Gypsum has a wide range of uses, covering many fields such as construction, medical treatment, and agriculture.

In the construction field, gypsum is the core raw material for making new wall materials such as gypsum boards and gypsum blocks. Boards made of gypsum have excellent properties such as light weight, fire resistance, and sound insulation, and are widely used in interior decoration and wall masonry of residential and commercial buildings. In addition, gypsum can also be used to make building gypsum powder, which can be used as a plastering material to make the wall surface smooth and flat.

In the medical field, medical gypsum has the function of fixing the fracture site. When a human bone is fractured, the doctor will mix the medical gypsum powder with water to make a paste, apply it to the fracture site, and wait for it to solidify to form a hard gypsum bandage, which can effectively fix the bone and promote fracture healing.

In the agricultural field, gypsum can be used as a soil conditioner. For saline-alkali land, gypsum can reduce the pH of the soil, improve the soil structure, increase the fertility of the soil, and promote the growth of crops. At the same time, gypsum contains elements such as calcium and sulfur, which can be used as fertilizers to provide nutrition for crops.

In the field of art, gypsum is often used to make sculptures, molds, etc. Because gypsum is easy to shape and solidifies quickly, artists can use it to create various exquisite sculptures; in mold making, gypsum molds can accurately replicate the shape of objects and are widely used in ceramics, casting and other industries.

2. Equipment required for gypsum grinding

Crushing equipment: Most gypsum raw materials are in block form, and the crushing equipment first breaks them into smaller particles. The jaw crusher is used for coarse crushing, which can crush large pieces of gypsum to a diameter of 20-30 cm; the cone crusher is used for medium crushing, which further refines the particles to 5-10 cm in preparation for subsequent grinding.

Grinding equipment: This is the core of gypsum grinding. The Raymond mill is suitable for general needs and can grind gypsum into 80-325 mesh powder with high efficiency; the high-pressure suspension roller mill can handle gypsum with slightly higher hardness and produce 80-400 mesh fine powder; the ultrafine mill can achieve finer grinding and process gypsum into 400-2500 mesh ultrafine powder to meet the needs of high-end industries.

Screening equipment: The vibrating screen is the main screening equipment, which is used to classify the gypsum powder after grinding. It separates gypsum powder of different particle sizes through high-frequency vibration. Fine powder that meets the requirements is collected, and unqualified coarse powder is returned to the mill for re-grinding to ensure uniform product particle size.

Auxiliary equipment: The feeder is responsible for feeding the crushed gypsum particles into the mill evenly to ensure stable operation of the mill; the conveyor is used to transport raw materials, semi-finished products and finished products between various equipment, and common ones are belt conveyors and screw conveyors; dust removal equipment such as pulse bag dust collectors can effectively collect dust generated during the grinding process, reduce pollution to the environment, and protect the health of operators.

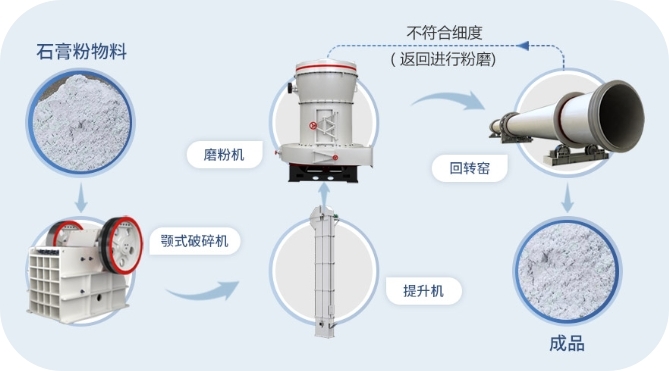

3. Gypsum grinding process flow

Raw material pre-treatment: The gypsum raw materials after mining are first cleaned manually or mechanically to remove impurities such as soil and stones on the surface. Then the cleaned gypsum is sent to the jaw crusher for coarse crushing, and then to the cone crusher for medium crushing to obtain gypsum particles with appropriate particle size.

Grinding operation: The crushed gypsum particles are evenly fed into the grinding mill through the feeder. In the grinding mill, the gypsum particles are squeezed and ground by the grinding roller and grinding ring, and are gradually crushed into powder. At the same time, the fan draws air into the grinding mill, so that the powder enters the analyzer with the airflow.

Grading and screening: The analyzer classifies the gypsum powder in the airflow. According to the set particle size standard, the qualified powder enters the cyclone collector through the analyzer, and the unqualified coarse powder falls back to the grinding mill for re-grinding.

Finished product collection and processing: The gypsum powder entering the cyclone collector settles under the action of gravity and is discharged through the discharge valve to become a finished product. The airflow enters the pulse bag dust collector, the residual dust is filtered and collected, and the purified air is discharged. Finally, the finished gypsum powder is packaged and stored as needed.

العربية

العربية Español

Español Português

Português Deutsch

Deutsch